information to be updated

Send tilbakemelding

Vannbasert uorganisk sinkrik belegg Dostawcy

Uorganisk sinkrike antikorrosive belegg

Uorganiske sinkrike belegg bruker uorganiske materialer som base og er rike på sinkpulver. Disse beleggene gir utmerket korrosjonsbeskyttelse for metallunderlag gjennom flere mekanismer, inkludert:

- Offeranodehandling: Sink fungerer som en offeranode for å beskytte metallet.

- Barriereeffekt: Gir en fysisk barriere for miljøelementer.

- Selvhelbredende: Belegget kan reparere mindre skader.

- Passivering: Danner et passivt lag som reduserer korrosjon.

Disse beleggene viser enestående værbestandighet, slitestyrke og vedheft, og opprettholder langsiktige antikorrosive effekter selv i tøffe miljøer.

Med økende miljøbevissthet blir vannbaserte uorganiske sinkrike belegg stadig mer populære på grunn av mangel på organiske løsemidler, miljøvennlighet, giftfri og enkle påføringsprosesser. De er mye brukt i marin engineering, broer og petrokjemisk industri, og regnes som essensielle materialer innen korrosjonsbeskyttelse.

-

Introduksjon Produksjonen av kaliumsilikat løsninger spiller en sentral rolle i ulike bransjer som landbruk, konstruksjon og kjemiteknikk. Disse løsningene, hovedsakelig laget ved å kombin...

CZYTAJ WIĘCEJ -

Introduksjon De siste årene har etterspørselen etter høyytelses vannavstøtende produkter skutt i været på grunn av økende fokus på holdbarhet og beskyttelse i ulike bransjer. En av de mest kritiske ingr...

CZYTAJ WIĘCEJ -

Introduksjon Natriumsilikatpulver , ofte referert til som vannglass eller flytende glass i flytende form, er en svært allsidig blanding med et bredt spekter av bruksområder på tvers av fler...

CZYTAJ WIĘCEJ

How Do Water-Based Inorganic Zinc-Rich Coatings Provide Lasting Protection for Metal Surfaces?

In the ever-evolving world of industrial coatings, water-based inorganic zinc-rich coatings have gained significant traction. This innovative solution not only addresses environmental concerns but also provides a durable, cost-effective way to protect metal surfaces from corrosion, especially in harsh environments.

The Growing Need for Corrosion Protection

Corrosion is a persistent problem for industries that rely on metal structures, such as construction, automotive, marine, and oil and gas. Over time, exposure to moisture, chemicals, and extreme temperatures can degrade metal surfaces, leading to costly repairs and maintenance. This is where water-based inorganic zinc-rich coatings come into play. These coatings act as a protective barrier, preventing the formation of rust and other forms of corrosion. But what makes them so effective and efficient?

What Sets Water-Based Inorganic Zinc-Rich Coatings Apart?

Water-based inorganic zinc-rich coatings consist of zinc dust suspended in an inorganic binder, typically based on silicate chemistry. The key to their corrosion resistance lies in the unique properties of zinc. When applied to metal surfaces, zinc acts as a sacrificial anode, corroding instead of the underlying metal. This protective mechanism is enhanced when the coating is inorganic and water-based, offering several advantages.

1. Environmentally Friendly Formulation

Unlike solvent-based coatings, water-based versions contain no volatile organic compounds (VOCs), making them a more sustainable and eco-friendly option. As environmental regulations tighten, businesses are under increasing pressure to reduce their carbon footprint and minimize the environmental impact of their operations. Water-based coatings are not only compliant with environmental standards but also contribute to a healthier work environment by reducing air pollution and toxicity.

2. Durability in Harsh Conditions

Inorganic zinc-rich coatings are known for their remarkable durability, especially in demanding environments. Their ability to withstand extreme temperatures, moisture, and exposure to chemicals makes them ideal for use in industries such as marine, offshore, and construction. These coatings provide long-lasting protection against corrosion, reducing the need for frequent touch-ups or re-coating, and thus lowering maintenance costs in the long run.

3. Excellent Adhesion and Abrasion Resistance

Water-based inorganic zinc-rich coatings offer superior adhesion to steel and other metals. The zinc particles in the coating chemically bond with the metal surface, ensuring a strong and durable layer. This makes the coatings resistant to abrasion, wear, and tear, which is especially important in heavy-duty industries where equipment is subject to constant physical stress.

How Do Water-Based Inorganic Zinc-Rich Coatings Work?

These coatings form a galvanic protection system that prevents corrosion by creating a bond between the zinc particles and the metal surface. When the metal is exposed to oxygen and moisture, the zinc particles in the coating corrode first, protecting the underlying metal from damage. The inorganic binder ensures that the zinc remains stable over time, even in challenging environmental conditions.

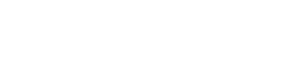

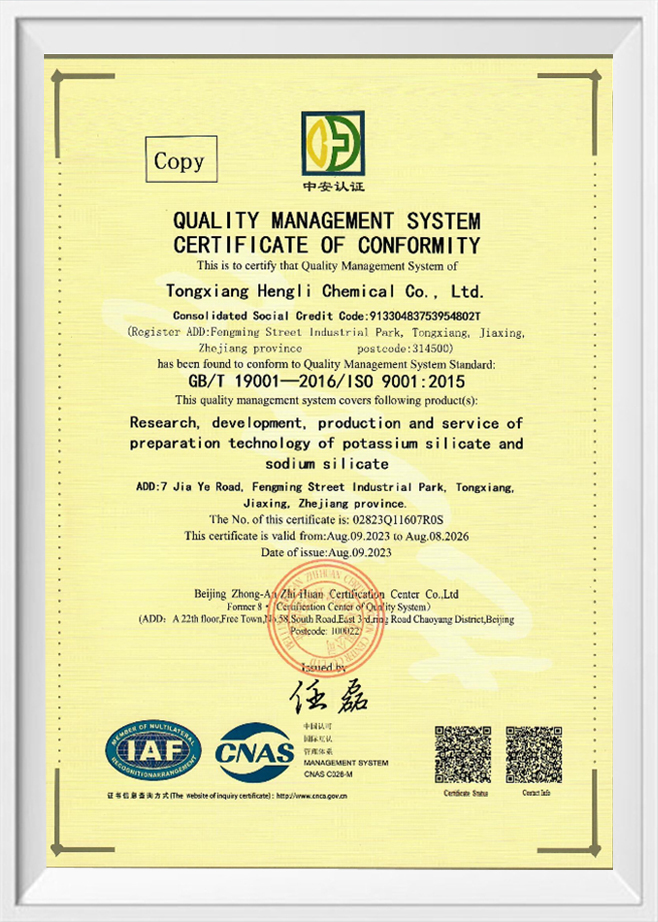

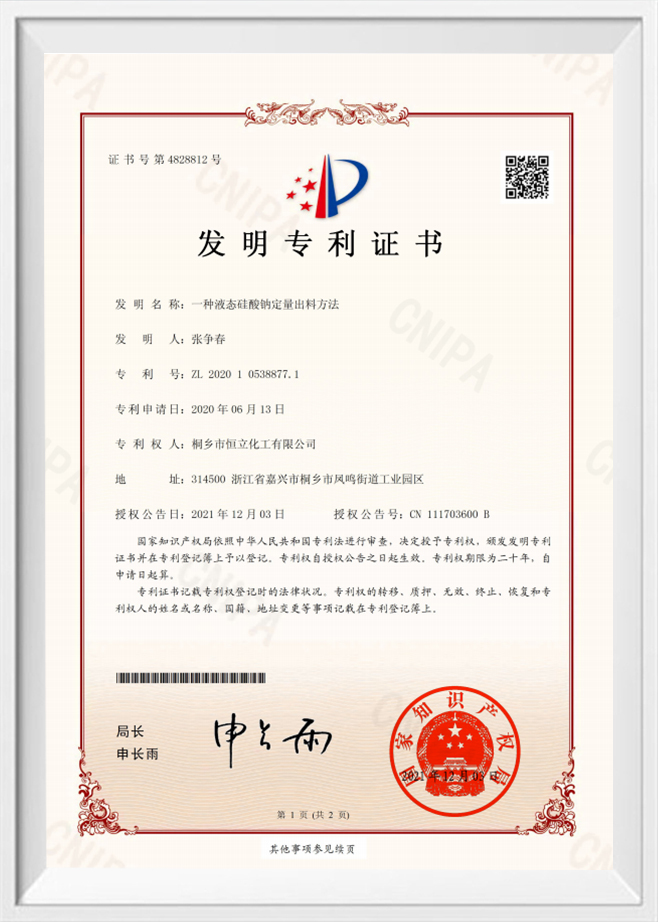

Tongxiang Hengli Chemical Co., Ltd. specializes in the manufacture of various inorganic materials, including sodium silicate, potassium silicate, lithium silicate, silica sol, and potassium methyl silicate. The company's extensive product range is used in various industries, including high-temperature-resistant adhesives and advanced coatings.

Tongxiang Hengli Chemical Co., Ltd. produces inorganic zinc-rich coatings that are formulated with precision to meet the highest standards of durability and performance. The company's commitment to research and development ensures that its products meet the evolving needs of industries that demand reliable and long-lasting corrosion protection.

Water-based inorganic zinc-rich coatings offer an effective and sustainable solution for protecting metal surfaces from corrosion. Their environmental benefits, combined with their excellent durability and performance in harsh conditions, make them the ideal choice for industries seeking long-term protection.With the growing emphasis on sustainability and long-term cost savings, these coatings are poised to become an essential part of the industrial coatings landscape.